Analysis and optimization on the biodegradable plate making process parameters using RSM-based Box–Behnken Design method

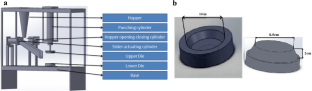

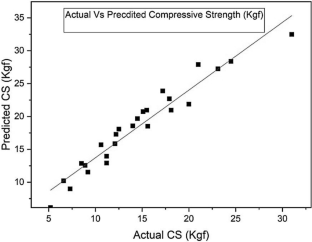

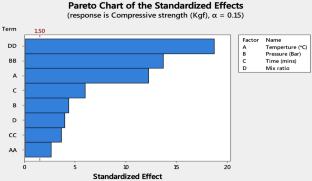

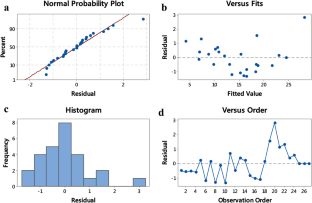

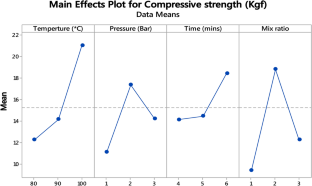

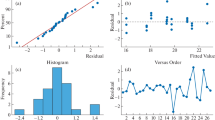

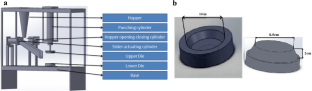

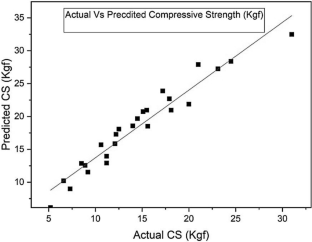

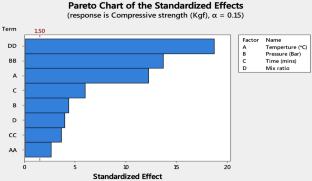

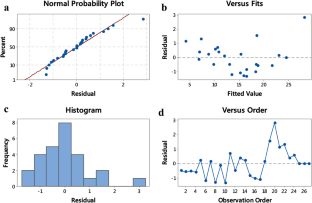

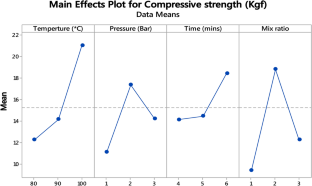

The present research work focused on fabricating Biodegradable Plate (BD plate) composed of rice husk ash, bagasse and corn starch which is harmless to the environment. Mechanical properties such as compressive strength, moisture absorption, solubility and infiltration time were examined in fabricated BD plate. Box–Behnken Design (BBD) and ANOVA analysis are employed to optimize the operating parameters includes raw material mix ratio, temperature on the die, pressure during the mixing process and time. Input factors such as temperature varies (80–100 ºC), pressure (1–3 bar), time (4–6 min) and Mix ratio (M1, M2 and M3) are coded into the BBD design. Lack of fit test, p and F value of the independent variables are calculated to confirm the significance of the regression model. Maximum compressive strength of 31 kgf is obtained at the optimal process parameters like temperature of 90 ºC, pressure of 2 bar, holding time of 6 min and Mix ratio of 2. The developed biodegradable plate serves as the alternative solution for plastic plates such that the developed plate withstands for 30 days free from fungus.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Subscribe and save

Springer+ Basic

€32.70 /Month

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

Buy Now

Price includes VAT (France)

Instant access to the full article PDF.

Rent this article via DeepDyve

Similar content being viewed by others

Preparation of Ecofriendly Viable Packaging Films Based on Pectin and Agro-Waste: Thermal and Mechanical Studies by Design of Experiments Approach

Article 01 October 2023

Response surface methodology (RSM) for optimization of thermochemical pretreatment method and enzymatic hydrolysis of deodar sawdust (DS) for bioethanol production using separate hydrolysis and co-fermentation (SHCF)

Article 28 August 2020

Engineering and functional properties of biodegradable pellets developed from various agro-industrial wastes using extrusion technology

Article 14 July 2015

References

- Al ME (2007) Continuous press for manufacturing biodegradable plates. United States Patent US 7,270,522 B2

- Berger E, Haussener E (1995) Method of making articles of edible or easily biodegradable material. United States Patent: US 5378418A:1–4 Google Scholar

- Miles C, DeVetter L, Ghimire S, Hayes DG (2017) Suitability of biodegradable plastic mulches for organic and sustainable agricultural production systems. J Am Soc Hortic Sci. 52:10–15

- Chaerul M, Fahruroji AR, Fujiwara T (2014) Recycling of plastic packaging waste in Bandung City, Indonesia. J Mater Cycles Waste Manage 16:509–518 ArticleGoogle Scholar

- Chiralt A, Menzel C, Hernandez-García E et al (2020) Use of by-products in edible coatings and biodegradable packaging materials for food preservation. Sustainability of the food system. Elsevier, pp 101–127 Google Scholar

- De D, Naga Sai MS, Aniya V et al (2021) Strategic biorefinery platform for green valorization of agro-industrial residues: a sustainable approach towards biodegradable plastics. J Clean Prod 290:125184 ArticleGoogle Scholar

- Dewi MY, Husni A (2020) Characterization of biobased alginate/glycerol/sunflower oil as biodegradable packaging. In: E3S Web of Conferences. EDP Sciences, p 03004

- Entry J, Donnelly P, Cromack K Jr (1993) Effect of nitrogen and carbon sources on lignin and cellulose degradation by Armillaria ostoyae. Eur J For Pathol 23:129–137 ArticleGoogle Scholar

- Gandhi P, Yadav M, Paritosh K et al (2020) Food wastes from hospitality sector as versatile bioresources for bio-products: an overview. J Mater Cycles Waste Manag 22:955–964 ArticleGoogle Scholar

- Ghanbarzadeh B, Almasi H, Entezami AA (2010) Physical properties of edible modified starch/carboxymethyl cellulose films. Innov Food Sci Emerg Technol 11:697–702 ArticleGoogle Scholar

- Hasan M, Kumar A, Maheshwari C et al (2020) Biodegradable and edible film: a counter to plastic pollution. IJCS 8:2242–2245 Google Scholar

- Ito S (1990) Method of producing edible vessel. United States Patent: US 49276564, pp 1–15

- Kandar MIM, Akil HM (2016) Application of design of experiment (DoE) for parameters optimization in compression moulding for flax reinforced biocomposites. Procedia Chem 19:433–440 ArticleGoogle Scholar

- Luchese CL, Pavoni JMF, Dos Santos NZ et al (2018) Effect of chitosan addition on the properties of films prepared with corn and cassava starches. J Food Sci Technol 55:2963–2973 ArticleGoogle Scholar

- Mahcene Z, Khelil A, Hasni S et al (2020) Development and characterization of sodium alginate based active edible films incorporated with essential oils of some medicinal plants. Int J Biol Macromol 145:124–132 ArticleGoogle Scholar

- Manimehalai N, Rajesh G, Balasubramanian S et al (2018) Gelatin based edible coating: preservation technique for seer (Scomberomorus guttatus) fish slices. Indian J Nutr Diet 55:177 ArticleGoogle Scholar

- Marcet I, Sáez S, Rendueles M et al (2017) Edible films from residual delipidated egg yolk proteins. J Food Sci Technol 54:3969–3978 ArticleGoogle Scholar

- Marismandani A, Husni A (2020) Development and characterization of biobased alginate/glycerol/virgin coconut oil as biodegradable packaging. E3S Web Conf 147:03016 ArticleGoogle Scholar

- Mullen CA, Boateng AA (2010) Catalytic pyrolysis-GC/MS of lignin from several sources. Fuel Process Technol 91:1446–1458 ArticleGoogle Scholar

- Natarajan Vivekk Velusamy Selvaraj NMVVM (2019) Eco-friendly and edible waste cutlery for sustainable environment. Int J Eng Adv Tech 9:615–624 ArticleGoogle Scholar

- Nandane AS, Jain R (2015) Study of mechanical properties of soy protein based edible film as affected by its composition and process parameters by using RSM. J Food Sci Technol 52:3645–3650 Google Scholar

- Ohtaki A, Nakasaki K (2000) Comparison of the weight-loss degradability of various biodegradable plastics under laboratory composting conditions. J Mater Cycles Waste Manage 2:118–124 Google Scholar

- Oladunjoye AO, Eziama SC, Aderibigbe OR (2021) Proximate composition, physical, sensory and microbial properties of wheat-hog plum bagasse composite cookies. LWT 141:111038 ArticleGoogle Scholar

- R R N Sailaja Bhattacharya KC, M V Deepthi, Pratik Roy,and Ameen Khan (2018) Challenges and opportunities-plastic waste management in India. Energy Resour Instit. 1–18

- Racmayani N, Husni A (2020) Effect of different formulations on characteristic of biobased alginate edible films as biodegradable packaging. In: E3S Web of Conferences. EDP Sciences, p 03003

- Saberi B, Thakur R, Vuong QV et al (2016) Optimization of physical and optical properties of biodegradable edible films based on pea starch and guar gum. Ind Crops Prod 86:342–352 ArticleGoogle Scholar

- Salar Behrestaghi F, Bahram S, Ariaii P (2020) Physical, mechanical, and antimicrobial properties of carboxymethyl cellulose edible films activated with Artemisia sieberi essential oil. J Food Q Hazards Control 7:36–44 Google Scholar

- Sangita Sood D (2018) Development and quality evaluation of edible plate. ARC J Nutr Growth 4:1–4 Google Scholar

- Shayesteh Haghdan SRaGDS (2016) Sources of lignin. Lignin in polymer composites, p 1–11

- Suresh R, Rajoo B, Chenniappan M et al (2021) Experimental analysis on the synergistic effect of combined use of ozone and UV radiation for the treatment of dairy industry wastewater. Environ Eng Res 26:200370–200375 Google Scholar

- Suresh R, Rajoo B, Chenniappan M et al. (2021) Treatment possibilities of electrical discharge non-thermal plasma for industrial wastewater treatment-review. In: IOP Conference Series: Materials Science and Engineering. IOP Publishing, p 012018

- Suresh R, Rajoo B, Chenniappan M et al (2021) Feasibility of applying nonthermal plasma for dairy effluent treatment and optimization of process parameters. Water Environ J 35:1038–1050 ArticleGoogle Scholar

- Tatyana Germanovna Korotkova SJK, Donenko AP, Bushumov SA, AaS D (2016) Physical properties and chemical composition of the rice husk and dust. Orient J Chem 32:3213–3219 ArticleGoogle Scholar

- Teriin (2018) Fact sheet on plastic waste in India. Energy and Resources Institute. 1–4

- Thakur R, Saberi B, Pristijono P et al (2017) Use of response surface methodology (RSM) to optimize pea starch–chitosan novel edible film formulation. J Food Sci Technol 54:2270–2278 ArticleGoogle Scholar

- Tharanathan RN (2003) Biodegradable films and composite coatings: past, present and future. Trends Food Sci Technol 14:71–78 ArticleGoogle Scholar

- Tropsa V, Ivankovic A, Williams JG (2000) Predicting residual stresses due to solidification in cast plastic plates. Plast, Rubber Compos 29:468–474 ArticleGoogle Scholar

- Wu L, Yick K-L, Ng S-P et al (2012) Application of the Box-Behnken design to the optimization of process parameters in foam cup molding. Expert Syst Appl 39:8059–8065 ArticleGoogle Scholar

- Yaghoobi H, Fereidoon A (2018) Modeling and optimization of tensile strength and modulus of polypropylene/kenaf fiber biocomposites using Box-Behnken response surface method. Polym Compos 39:E463–E479 ArticleGoogle Scholar

- Zhang X, Zhao Y, Li Y et al (2020) Physicochemical, mechanical and structural properties of composite edible films based on whey protein isolate/psyllium seed gum. Int J Biol Macromol 153:892–901 ArticleGoogle Scholar

- Zhou HL, Yunxia, Song, Yanlin (2011) Green plate making technology based on nano-materials. Int Con Digital Print Technol 2:298–299 Google Scholar

Acknowledgements

This research work was funded by Kongu Engineering College under the scheme of Entrepreneurship Development and Innovation Institute under Innovation Voucher Programme, File No. II-01/2/2019-EDII-EDII.

Author information

Authors and Affiliations

- Department of Mechatronics Engineering, Kongu Engineering College, Perundurai, Erode, Tamil Nadu, 638060, India C. Maheswari, B. Meenakshi Priya, S. Sudhahar, B. Prabhu Raj & B. Lokesh

- Department of Civil Engineering, Sanskrithi School of Engineering, Puttaparthi, Andhra Pradesh, 515134, India A. S. Ramya

- Department of EEE, Nandha Engineering College, Perundurai, Erode, Tamil Nadu, 638060, India G. Ramani

- C. Maheswari